outline the steps of manufacturing portland cement

Manufacture of Cement- Materials and Manufacturing

Manufacturing of cement involves various raw materials and processes. Each process is explained chemical reactions for manufacture of Portland Cement.

دردشة على الإنترنت

The Manufacture of Portland Cement - NZIC

Portland cement (the only type of cement in common use today) is manufactured in a four step process. Step 1 - Quarrying Limestone and a 'cement rock' such as clay or shale are quarried

دردشة على الإنترنت

Manufacturing of Portland Cement – Process Applications

22 小时之前 Manufacturing Process of Portland Cement. The manufacturing process of Portland cement starts with grinding and mixing the raw materials at specific proportions. Then the

دردشة على الإنترنت

Portland Cement Manufacturing – Ordinary Portland

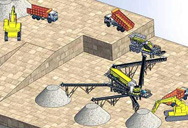

The Portland cement manufacturing process can be divided into 6 steps: raw material crushing, pre-homogenization, fine grinding, clinker production, cement grinding, cement packing, etc. In these processes, we need the assistance of

دردشة على الإنترنت

How Cement is Made - Portland Cement Association

Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden. Concrete is the most widely used resource in the world after water. Cement is manufactured from materials heated together at

دردشة على الإنترنت

From Raw Materials to Concrete: The Science of Portland Cement ...

LESSON 1:INTRODUCTION TO PORTLAND CEMENT. Lesson objective: Define Portland cement and explain its significance as a fundamental material in the construction industry. Identify the constituents of Portland cement, including limestone, clay, iron ore, and gypsum, and understand their respective roles in the cement manufacturing process.

دردشة على الإنترنت

11.6 Portland Cement Manufacturing - U.S. Environmental

11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic ... The second step in portland cement manufacture is preparing the raw mix, or kiln feed, for the

دردشة على الإنترنت

How Portland Cement is Made? Manufacturing

Portland cement can be made by following two different processes – a dry one and a wet one. Joseph Aspdin first made portland cement in his kitchen stove in England in the 19th century. Lime and silica make up approximately 85% of

دردشة على الإنترنت

11.6 Portland Cement Manufacturing - US EPA

1971year8month17day 11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of ... The second step in portland cement manufacture is preparing the raw mix, or

دردشة على الإنترنت

What is the Manufacturing Process of Portland Cement?

The manufacturing process of Portland cement is a sophisticated and multi-step procedure that transforms raw materials into a vital construction material. Many people believe it’s a simple process, but in reality, it involves several key stages, each critical to

دردشة على الإنترنت

Portland Cement Manufacturing – Ordinary Portland Cement

The Portland cement manufacturing process can be divided into 6 steps: raw material crushing, pre-homogenization, fine grinding, clinker production, cement grinding, cement packing, etc. In these processes, we need the assistance of different kinds of cement equipment , such as cement kilns, cement mills, and cement crushers.

دردشة على الإنترنت

Manufacturing Process of Cement - Construction How

2020year4month7day The primary raw materials for the mass production of cement can either be calcareous or argillaceous. The former ingredient is obtained from limestone, marl, cement rock, chalk, etc., whereas the latter one is procured from clay, slate, blast furnace slag, shale, etc. The process of manufacturing cement can either be a wet process or a dry process.

دردشة على الإنترنت

Manufacture Of Portland Cement Process - civil learners

2019year11month30day In this article we briefly explained the manufacture of portland cement with the process.The processes used for the manufacture of read more. Skip to content. Menu. Home; Materials of construction. Stones; Timber; Cement; ... The cement then is used for several engineering purposes and for further manufacturing of cement and products.

دردشة على الإنترنت

Cement manufacturing process PPT Free Download - SlideShare

2014year6month10day This document discusses Portland cement and the cement manufacturing process. It begins with an overview of what cement is and how it is used to make concrete. It then describes the industrial process for manufacturing cement, involving grinding raw materials like limestone and clay at high temperatures in a kiln to form clinker, which is then pulverized with

دردشة على الإنترنت

Cement Manufacturing Process: Know Extraction, Processing

2024year9month10day Steps of Cement Manufacturing. The steps involved in cement manufacturing are as follows: Quarrying: Raw materials such as limestone and clay are extracted from quarries or mines.; Crushing and Grinding: The extracted raw materials are crushed and ground into a fine powder.; Blending: The crushed and ground raw materials are blended in specific proportions

دردشة على الإنترنت

Manufacturing of Cement By Dry and Wet Process

Burning: In this operation, the slurry is directly fed into a long inclined steel cylinder called a Rotary kiln.In this kiln there are 3 different zones shown in fig. below. Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet

دردشة على الإنترنت

A Comprehensive Guide to the Cement

2024year9month5day The Manufacturing Process of Cement. Now, let’s explore the steps involved in the cement production process in more detail: 1. Mining and Crushing. The process of making cement begins with mining, where raw

دردشة على الإنترنت

Cement Production and Manufacturing Process

Each step of cement manufacturing, physical conditions and reactions occurred are explained here. ... Portland cement manufacturing process - Flow diagram Importance of gypsum in cement industry. Gypsum can decrease the

دردشة على الإنترنت

Portland Cement Manufacturing Process In Cement Plant AGICO

Cement Grinding: cement grinding is the final stage in Portland cement manufacturing. In this step, clinker will be ground in grinding mill to reach the qualified fineness of cement product. During the grinding, we usually add gypsum, fly ash and other raw materials into the cement to realize the different usage of cement.

دردشة على الإنترنت

Manufacturing Process of Portland Pozzolana Cement (PPC ...

Discover the manufacturing process of Portland Pozzolana Cement (PPC) and its key attributes explained by Prism Cement. prismjohnson ; TOLL FREE NO: 1800 572 1444; ... Features of Portland Pozzolana Cement. It is having low heat of hydration which in turn provides greater resistance to crack developments in concrete.

دردشة على الإنترنت

Cement - Extraction, Processing, Manufacturing Britannica

6 天之前 Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

دردشة على الإنترنت

Manufacturing of cement PPT Free Download - SlideShare

2018year1month10day 7. MANUFACTURING Of PORTLAND CEMENT Portland cement is made by heating raw materials rich in oxides of silicon, calcium, aluminum and iron to temperatures of around 1200 - 1400o C. The chemical reactions that occur within the partially molten mass result from the formation of the four main cement materials. Tricalcium silicate (CaO)3•SiO2 C3S 45

دردشة على الإنترنت

2 Types of Manufacturing of Cement - Wet and Dry Process

The steps involved in the wet process of cement manufacturing are given below: Cement is manufactured using an earlier, less popular method called wet production. In the wet process, which involves grinding raw materials into a slurry and then feeding them into a rotary kiln for drying and calcination .

دردشة على الإنترنت

Diagram of the Portland cement manufacturing process. Source

Download scientific diagram Diagram of the Portland cement manufacturing process. Source: The authors. from publication: Using waste energy from the Organic Rankine Cycle cogeneration in the ...

دردشة على الإنترنت

Portland cement Manufacturing, Composition, Uses Britannica

2024year11month22day portland cement, binding material in the form of a finely ground powder, usually gray, that is manufactured by burning and grinding a mixture of limestone and clay or limestone and shale.The inventor Joseph Aspdin, of England, patented the basic process in 1824, naming it for the resemblance of the cement when set to portland stone, a limestone from the Isle of

دردشة على الإنترنت

شاهد المزيد

- كرة مطحنة وسحق لشبكة الكوارتز السيليكا 600

- تستخدم آلة الحجر المسحوق

- كسارة متنقلة على الإيجار

- إنتاج الرمال في مصر

- کامل خرد کن 500 تن در ساعت

- مصنع كسارة الفحم 400tph

- صنع معدات صنع الرمال الصخرية في جنوب أفريقيا

- سحق النبات الأسعار

- مصنع الكسارة الخبث الهند الصانع في الهند

- استخراج از دانه ها

- كسارة الفك الحجر الجيري

- تستخدم في مصر كسارة مخروطية

- روشهای استخراج معدن سنگ آهک در هند

- شراء كسارة في الولايات المتحدة الأمريكية

- تبديل الكسارة الفكية ذات التبديل الفردي والمزدوج